Two Liberty Ships which survived WWII were later used as heavily-modified test hulls by the US Navy, the stranger of the two being YAG-37 which was powered by aircraft propellers.

(A WWII Liberty Ship.)

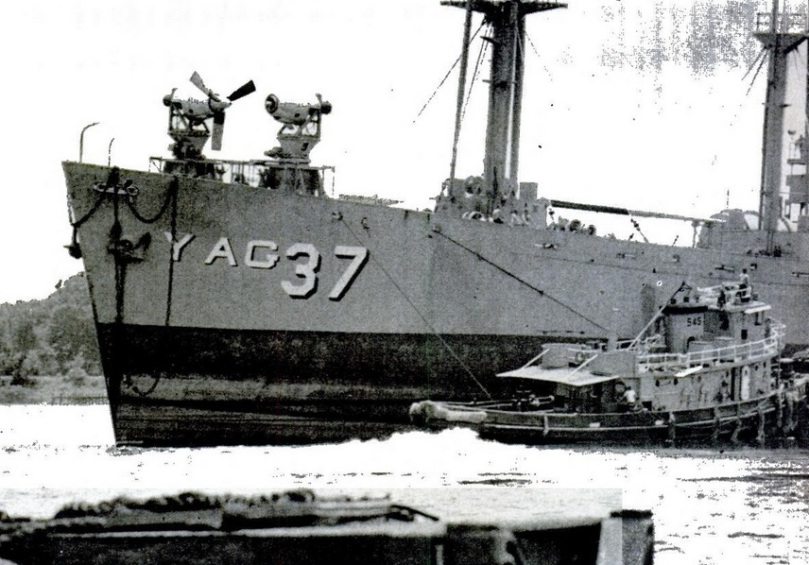

(YAG-37, the former WWII Liberty Ship S.S. John L. Sullivan, during the turboprop experiments.) (US National Archives photo)

Liberty Ships

The EC2-S-C1, or Liberty Ship, is probably the most famous merchant ship design in history. Its objective was simple: to be such a basic, cheap, and fast-to-build freighter that it would defeat Germany’s u-boat effort simply by having more coming off slipways faster than the Germans could sink them.

A Liberty Ship measured 441’6″ x 57′ x 37’4″ and had five cargo holds with three boom masts. About 10,000t of cargo could be carried.

The program started several months before the USA had even entered WWII. Eighteen shipyards made Liberty Ships. Each ship’s $1.99 million cost ($35.4 million in 2022 money) was subsidized by the federal government, with the first hull started in September 1941.

(The Liberty Ship S.S. John L. Sullivan, the future YAG-37, several months after WWII ended.) (photo via pacificwrecks.org website)

Liberty Ships were not exactly perfect freighters. They used a cheap, old-fashioned triple-expansion steam engine and had a top speed of just 11 kts. The hulls were made of inexpensive killed steel and used fast welding instead of riveting. The intended hull lifespan was only 60 months, which in many cases after WWII was exponentially exceeded as Liberty Ships were sold off to freight companies. Some were still in commercial use in the late 1970s.

Whatever their flaws, the Liberty Ship idea worked. During 1940 merchant tonnage to Great Britain was being sunk at a ratio of 4½ : 1 to new construction. By December 1941 this negative ratio had improved to 2¼ : 1 and by late January 1943 was at an even 1 : 1. At the same time, Allied anti-submarine tactics advanced and a greater proportion of u-boats were themselves being sunk. By mid-1944 new merchant tonnage was exceeding losses at a 1 : 2 ratio and strategically, Germany had lost the battle for the Atlantic.

A total of 2,710 Liberty Ships were completed. During WWII 207 were sunk in combat, the majority (125) by submarines. Another 46 sank during WWII due to non-combat causes such as running aground, collisions, or the Liberty Ship simply falling apart in rough weather – which also occasionally happened after WWII with Liberty Ships in merchant service.

Of the 2,357 which survived WWII, some were immediately auctioned off as surplus and the balance assigned to the US Maritime Commission (MARAD) from 1947 onwards. MARAD mothballed them for possible need in a future war (in 1970, it still held 434 in inventory) but gradually whittled down the number through periodic sales or scrappings.

MARAD ships remained government property and could be either chartered out to steamship lines, or transferred to the US Navy upon request.

S.S. John L. Sullivan

This Liberty Ship was built by Permanente Metals Corporation at their #2 Shipyard in Richmond, CA near Oakland. The reciprocating engine was made by Willamette Iron & Steel in Portland, OR. The ship was named after the athlete John Sullivan, who in 1882 became the first champion of what is now considered “modern” boxing. Construction began on 2 May 1943 and completed on 7 June 1943. This astonishing speed was actually common for WWII Liberty Ships which had an average build time of only 42 days.

S.S John L. Sullivan was operated by the War Shipping Administration during WWII with a nominal homeport of San Francisco, CA.

after WWII

In April 1946, S.S. John L. Sullivan arrived in the Philippines to transport home demobilized Japanese troops (including seven generals), a female detachment of the Japanese Red Cross, and civilian laborers. The ship stopped first in Taiwan to disembark those of Chinese descent, then in South Korea for those of Korean descent, and finally in Uraga in occupied Japan.

(S.S. John L. Sullivan with Japanese soldiers aboard in 1946.) (photo by Edwin Fitchett)

After disembarking the last passengers S.S. John L. Sullivan went to Yokohama for repairs and then back to the Philippines, and from there to the USA. In late 1946, title of the ship was passed to the United States Department Of Commerce.

S.S. John L. Sullivan was chartered by the military again during the Korean War, seeing use during the 1951 – 1952 winter and into the late summer of 1952.

The ex-S.S. John L. Sullivan was one of several surplus WWII Liberty Ship hulls acquired by the US Navy from MARAD during the 1950s for use in various experimental projects.

(US Navy hull number YAG-36 was assigned to the former S.S. Floyd W. Spencer, and behind it, YAG-37 to the former S.S. John L. Sullivan. YAG-36 was slated to be an experimental mine warfare ship but little work was ever really done with it and the US Navy sold it for scrap in 1960.) (photo via navsource website)

YAG-37

basic concept

The general idea for YAG-37 needs little elaboration. It was to be a large hull powered by above-decks aircraft propellers (airscrews) as opposed to a ship’s propeller beneath the waterline.

A type of small civilian hydroplane called “swamp buggies” or “Everglades airboat” in the USA, had already existed for decades. However these were little flat-bottom skimming type craft, not in-displacement ships. These skimming types had seen limited niche use during the first world war and again during the second, but were a different concept than a displacement-type hull moved by an aircraft propeller.

During WWII a mass-production application of this concept in a displacement-type hull was the Imperial Japanese Navy’s “E Type”. These were wooden amphibious assault craft 63’2″ in length with a normal draught of 1’6″. They were powered by an above-deck aircraft engine and propeller.

These were smaller than the famous Daihatsu class (most of which actually belonged to the Imperial Japanese Army) but larger than the navy “A Type” and army Shohatsu class landing craft. The “E Type” was intended for very shallow waters or where underwater obstructions might be present; such as lagoons or estuaries.

US Army intelligence initially designated the “E Type” as “Japanese hydroplaning type” but it was discovered that this was not completely accurate; even empty at full speed the “E Type” still had a draught of about one foot.

The Japanese did not consider these ideal ships. They were loud, unreliable, and even when empty the top speed was only 10 kts. Some later had the aircraft engine removed for use as a towed barge and very few survived WWII.

start of project

In 1957, YAG-37 was selected for this project. There was no “USS John L. Sullivan”, the former civilian name S.S. John L. Sullivan was struck and the ship was known only by its hull number. (Ironically a different John L. Sullivan had been Secretary of the Navy from 1947 – 1949). In the US Navy system, the YAG-__ prefix is for “miscellaneous service auxiliary” and could be either a formally commissioned warship or an uncommissioned “in-service vessel”, of which YAG-37 was the latter.

PROJECT OBJECTIVES

general discovery

This was not any one mission in particular but rather just a real-world, “hands on” test of what had until then been a pen & paper theory.

The above-decks turboprop arrangement was never intended to be the sole propulsion for surface combatants….even before work started nobody thought this would ever be suitable for a destroyer. It was intended as a new technology for niche uses, either as a supplemental way of moving a ship or aboard smaller non-combat types, a new low-power method.

restricted water operations

One field of interest was exploring a way to operate in shallow, obstructed, or otherwise restricted waters. Here, the problem is the danger of a normal ship’s propeller and rudder striking the seafloor or becoming fouled. Future types which might benefit from this included tugboats, small minesweepers, fuel lighters, transports, and amphibious assault craft.

(A WWII small harbor-use tugboat, or YTL, still in US Navy service during the Vietnam War. WWII tugs needed the broadest possible propeller to transfer as much energy as possible into the water. Here the propeller and rudder skeg are actually lower than the YTL’s keel.)

Minesweepers were of particular interest. During the latter part of WWII, and then especially during the Korean War, much minesweeping was done in shallow or constricted waters. The design of American inshore WWII minesweepers had to balance being small enough to “work tight” in shallow constricted waters, but, still big enough that they had the seaworthiness to cross the open ocean in bad weather.

(The YMS, or auxiliary motor minesweeper, was the smallest shallow-water minesweeper class the US Navy considered safe to self-deploy across open seas during WWII. Anything smaller usually had to be transported as cargo. They were 136′ long and displaced 270 tons, with a 32 man crew. Above is USS Ruff (AMS-54) which had been YMS-327 during WWII. The YMS category was disestablished in 1955. USS Ruff decommissioned on 14 November 1969, the very last WWII YMS still in the US Navy by then.) (photo via navsource website)

The US Navy considered that it might be ideal to design a future inshore mineweeper with a big yet squat, low-draught hull via having all propulsive and steering components above the weather deck. This would also eliminate the danger of explosions in the water damaging the propeller shaft or rudder, meanwhile the areas beneath the center of gravity normally used for engines could be packed with buoyant shock-absorbing material.

Use of the above-decks propulsion concept for minesweeping dovetailed with the experiments the US Navy was also doing to “barrage-breaking” mine clearance, which YAG-37 was also intended to be used in, which is outlined further below.

enhanced maneuverability

Ships steer with a rudder, meaning that the pivot point is the vessel’s extreme stern. In a textbook sense, a more ideal position would be exactly amidships, which is impossible with a normal propeller and rudder set-up.

One solution is a cycloidal propulsor. This is an array of spinning foils set vertically onto the ship’s keel. By altering the pitch of some or all of the spinning foils, almost instantaneous directional changes can be accomplished, and the ship can maneuver with great precision. In the 1950s they were not at all new technology. USS Alarm, a patrol craft in commission from 1874 – 1885, had a primitive cycloidal propulsor. During WWII, several German minesweepers and a Japanese cable layer had them.

The obvious drawback is that since a cycloidal propulsor spins vertically beneath the keel, it effectively increases the whole ship’s draught by whatever the length of the foils is. They also have problems moving a ship at appreciable forward speeds.

The US Navy felt a more ideal solution would be to replace the normal propeller & rudder set-up with four-point propulsion above the waterline. This would offer unlimited maneuverability in all directions, but without having anything project beneath the keel. Naval types that might benefit from this would be tugboats, salvage ships, oceanography ships, submarine rescue ships, cable layers, and dredges. Perhaps the technology might not only be useful for future designs, but maybe also for retrofit onto WWII warships still in the fleet.

a more esoteric idea

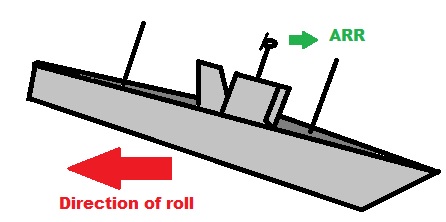

Not part of the “core curriculum” for the YAG-37 trials, but still of interest, was a brief marine engineering fad of the late 1940s and 1950s called active roll reduction (ARR).

During the first peacetime winter (1945 – 1946) and then into the late 1940s, one of the major concerns within the US Navy was topweight reduction.

Especially aboard destroyers, WWII saw the introduction of myriad new radars, radio antennas, anti-aircraft weapons, and other kit installed above the centre-of-gravity with even more still under development when WWII ended in September 1945. Each generation seemed to be bigger and heavier than the previous. Field-effect transistors would not be invented until the late 1950s and microchips were still science fiction, so the post-WWII US Navy had every reason to worry this trend would continue unabated.

(USS Hughes during the 1944 liberation of Panoan, an outlying island of the Philippines. USS Hughes later survived the two 1946 nuclear tests at Bikini and the radioactive ship was sunk as a conventional bombing target in 1948.)

As just one example the above photo shows USS Hughes (DD-410), a Sims class destroyer of WWII. Everything circled is additional topweight at or above the ship’s centre-of-gravity which had not been planned when the Sims class was designed in 1936. The photo does not show “hidden weights” such as power cables and waveguides for the radars or ammunition for the light AA guns. During WWII the US Navy tried to manage this issue on the Sims class by replacing wood lifeboats with rafts and lowering the aft searchlight, but there was still tons of topweight which had never been anticipated.

Now in the 2020s, naval historians often overlook the US Navy’s post-WWII topweight-reduction concerns as they were overshadowed by operation “Magic Carpet”, the mass sealift of GIs home, and the need to demobilize much of the fleet – both also happening at this time. But it was not a trivial concern. The US Navy was willing to hear out any idea. One which was widely done, was to simply strip off WWII 20mm and .50cal AA guns, eliminating their weight (and also reducing crew sizes). Another tried experimentally was to replace steel deckplates of interior walkways with light-alloy grates, shaving off a few tons above the centre-of-gravity.

These were passive solutions. ARR was a proposed active solution. Here, a small turboprop engine and airscrew controlled by an inclinometer would be set high upon a sturdy mast. Using its height above the centre-of-gravity as additional “leverage”, the turboprop would generate thrust in the opposite direction of whichever way the ship was rolling.

As waves naturally rock a ship back & forth, the ARR turboprop would need to work two directions. An opposed pairing was rejected as impractical already in the 1950s. A second idea was for one turboprop on a turntable to spin it as the hull rolled past 0°. A third idea was for for a fixed turboprop fitted with a “β-pitch” airscrew; where the pitch of the blades could alter past 90° flat, effectively “blowing in reverse”.

ARR was a fringe concept at best, albeit briefly an intriguing one in the shipwright community, fraught with real-world challenges. It would have to be mounted at the very top of a tall sturdy mast (ironically, itself contributing new excess topweight) which would interfere with optimal placement of radars and antennas. It was doubted the US Navy would really want to go through all this for a device offering niche usefulness.

ARR was never tested aboard YAG-37 or any other warship, although some knowledge obtained from the tests was theoretically interesting to ship designers. By the early 1960s underwater stabilizing fins had been developed and this idea faded into obscurity.

THE YAG-37 PROJECT

In its new guise YAG-37 had a “crew” of 20, all of which were in some way connected to the project and not expected to live aboard the ship.

(clipping from Popular Mechanics magazine)

shipyard

Conversion of the former S.S. John L. Sullivan into YAG-37 was done by Rawls Brothers shipyard in Jacksonville, FL. Started as the Merrill-Stevens Company in 1890, during WWII this shipyard did repairs to small warships and “finishing” work to vessels built elsewhere. It was located on St. Johns River in downtown Jacksonville.

In 1953 Merrill-Stevens transferred it to the Rawls brothers. During the early Cold War period, Rawls Bros. enjoyed steady business maintaining deactivated WWII warships, which even in mothballs needed occasional upkeep and rust abatement. The location was only 26 miles from the Green Cove Springs, FL mothball anchorage, which from 1946 until its closure in 1962 housed up to 600 deactivated WWII warships. During 1953 Rawls also built eight small tugboats for the US Army Watercraft Corps.

(At the same time YAG-37 was being converted in the foreground, the inactive USS Frazier (DD-607) was drydocked at Rawls Bros. This WWII Benson class destroyer had been in mothballs since 1946. It was never reactivated and was scrapped in 1972.) (photo from Jacksonville Seafarer magazine)

From 1963 onwards Rawls Bros. Shipyard went through several ownership changes, with the last being the Terex Corporation. This shipyard was shut down and razed in 1992. As of 2022 the location (about 400 yards southwest of Daily’s Place and the Jaguars football stadium) is an empty lot on Bay Street.

hull changes

All of the WWII Liberty Ship propulsive elements: the boilers, their condensers, the reciprocating engine, the steam return lines; were all ripped out of the hull. The top of the smokestack was covered by a metal plate. The propeller was removed. The rudder was retained; as it was reasoned that it might be useful with the hull under unpowered tow.

For the planned second phase of the experiment, the WWII cargo holds were partially filled with what was described as “buoyancy materials”. These were either foam “ping pong balls” or empty 55gal drums; quite possibly both. Empty drums were used by the US Navy at that time in SINKEX target ships, as the closed drums not only held buoyancy in a flooding compartment but also could form a “crumple zone” where the shock of explosions would (hopefully) deform the drums instead of being transferred throughout the ship’s structure.

During WWII, Liberty Ships had three 120V generators powered off the reciprocating engine. With it now gone, these were removed as well. Instead a single 120kW Allis-Chalmers generator was installed on the aft deck, powered by a commercial General Motors 3268A diesel. This provided electricity to the rotating mounts for the four turboprops, the new control panel in the WWII wheelhouse, and the small amount of current needed for lighting and other miscellaneous things.

During WWII two small compartments near the Liberty Ship’s forward bilge, called “low tanks”, were designed that they could be used for either dry or liquid cargo. These were retained for a ballasting system, as YAG-37 rode very high in the water with no freight, boilers, or engine aboard.

(YAG-37 being assisted into Panama City, FL by tugs, riding high in the water.)

Three portable air compressors and an accumulator tank were installed on the main deck. These powered the anchor and the rudder.

(The accumulator, pneumatic piping, and two of the three portable air compressors.)

A centralized CO² fire suppression system designed by the Kidde fire extinguisher company was installed.

propulsion

The four turboprops were Pratt & Whitney T34s. Development of the T34 started late in WWII to a US Navy request, however it was not entirely expected that it would be ready before WWII ended, which at the time was expected to be sometime in 1946. When WWII instead ended in September 1945, only basic ideas were done.

After WWII the military still had interest in the project, as did Pratt & Whitney. The US Army’s air forces (to become the independent US Air Force in September 1947) envisioned it powering yet-undesigned bombers and transports. Pratt & Whitney had high expectations for civilian orders and planned to market it as the “Turbo Wasp”, hopefully capitalizing on the public fame of the completely unrelated WWII Wasp / Double Wasp / Twin Wasp family of piston engines.

In September 1950, a prototype was tested on a disarmed and grotesquely-modified B-17G Flying Fortress left over from WWII assigned to Wright-Patterson AFB.

The tests were successful and the T34 was a powerful engine, requiring the Flying Fortress’s pilot to hold a constant rudder to counteract the four-bladed propeller’s torque.

A technical success, the T34 turned out to be a disappointment financially. The only major military contract was 200 engines for the US Air Force’s fifty C-133 Cargomaster heavy airlifters.

Only a few other small military orders were placed. The T34 was a commercial flop as well. Many airlines were content to use piston engines a few more years until the Boeing 707 and Douglas DC-8 became available, and then just proceed straight to jets.

The four engines used aboard YAG-37 were already government property. They had been stripped off a C-121F, a turboprop version of the piston-powered C-121 Super Constellation which itself was a postwar version of the WWII C-69 Constellation. The C-121F had not been a success and only six were built, split between the US Air Force and US Navy.

Aboard YAG-37 the four T34 turboprops were installed in mounts atop electrically-swiveled turntables which incorporated the lower mounting of WWII Mk2 40mm AA guns. The turboprops could be rotated 360° all together, in pairs, or individually.

(The forward two turboprops.)

(The aft two turboprops.)

The turboprops burned JP-4 fuel. This was carried in two huge 10′-diameter tanks on the weather deck ahead of the Liberty Ship superstructure. An above-decks location was selected as inside metal pipes, JP-4 can build up static electricity as it flows and this eliminated the possibility of a fire in the WWII cargo holds. Each turboprop had an integral gear-type fuel pump and each was provided with a fuel filter.

(Close-up of the port side fuel tank. These were coated with a corrosion inhibitor and each had its own filling manifold. The three porthole windows in the superstructure are the WWII wheelhouse, where now the entire YAG-37 was controlled out of.)

The T34’s driveshaft had an internal brake which, once power fell below 45%, could rapidly stop the propeller.

On a normal aircraft installation these turboprops had spark-type starter but for the YAG-37 experiments they used compressed air starter pods designed by Air Research Corporation.

(photo from Jacksonville Seafarer magazine)

The type of actual airscrew, or propeller, used with the T34s was a cause of discussion (described further below) during the planning phase. The design chosen was a variable pitch, three-bladed model made by the Hamilton Standard company in Connecticut. The blades had a slight “twist”.

RESULTS

The story of YAG-37 is ultimately one of a failure. Of all the attributes studied in 1957, only one reached a positive conclusion. The remainder were problematic and additional unforeseen problems were discovered.

maneuverability

This was the success of the concept. YAG-37 was extremely maneuverable. Motion in forward, reverse, and lateral (sideways) directions was possible. YAG-37 could also “crab walk” (move forward but at a heading diagonal to where the bow was pointed) and perform spins. The formerly clumsy Liberty Ship hull was able to maneuver around buoys and on at least one instance, tie up to the pier without tugboat assistance.

(During the 1957 experiments, tugboats usually assisted YAG-37 anyways for safety’s sake. The one here is a WWII warship itself, the Hisada class USS Accohanoc (YTM-545) which was normally based at Mayport, FL during the Cold War. USS Accohanoc decommissioned in 1987 and was renamed TD-25 by the US Maritime Administration, being used to tend the James River, VA mothball fleet. It flooded out during a 1999 storm and was scrapped.) (photo via Popular Science magazine)

a low power disappointment

For the envisioned future uses, the above-decks turboprop set-up would have either been a secondary propulsion or the sole method for niche types such as harbor lighters with no need for speed anyways.

That said, the power output was unimpressive. The US Navy estimated that 8 kts would be the maximum speed for YAG-37. However two publications, the Shipbuilding & Shipping Record and Shipping World magazine, both stated that YAG-37 only ever achieved 7 kts, and that being only in normal forward motion in calm seas, on an empty hull devoid of cargo, fuel, sensors, or weapons.

Raw horsepower was not an answer. During WWII, a Liberty Ship’s reciprocating steam engine and underwater propeller gave 2,500hp for a speed of 11 kts. The four T34 turboprops aboard YAG-37 were normally run at around half-power for safety and maintenance reasons, each generating 3,000hp at that level for a total of 12,000hp. Hence, in terms of raw horsepower YAG-37 had a +380% advantage but was 36% slower than S.S. John L. Sullivan.

A crude equation to calculate generated motion effect of airscrew size is Τ=QCª where the desired effect (T), is equal to the volume in cubic feet of air passed through the airscrew’s spin disc at any moment plus the approach speed of the air (Q), and (Cª ) which is the net increase of the air’s velocity behind the propeller.

The US Navy was not stupid and knew this in 1957. During the planning stage, various types and sizes of airscrew blades in varying numbers were proposed for YAG-37. The model offered by Hamilton Standard was selected as it was somewhat advanced but also affordable, available, and feasible for the project.

After the project ended in 1947 the US Navy concluded that to even match the Liberty Ship’s WWII speed would have required expensive exotic airscrews of cartoonishly-large size for types like future salvage ships or cable layers. Aboard smaller types envisioned as candidates for this technology like derricks or dredges, the 1957 design itself would be proportionally too big.

An interesting thing discovered was that even at the same airscrew RPMs and engine power, YAG-37 had noticeable performance differences on hot, humid days vs colder weather with a headwind. This was in no way a limiting thing but would have required any candidate ship to have extensive weather-to-engine graphs made – again, another expense and headache.

vibration

As it was a closely-run experiment, the WWII 40mm AA gun mountings for the aircraft turboprops aboard YAG-37 were maintained to a high degree and the arrangement ran smoothly. However the experiment concluded that if the mounts loosened or went out of alignment, any minute oscillation of the spinning airscrew would translate as strong vibrations onto the ship’s hull.

“day to day use” problems

During WWII even something as large as a heavy cruiser could take waves over the foredeck during a severe storm. As aircraft engines are relatively fragile things, some sort of solution to that issue would have to be invented down the line.

A related concern (not a problem in summertime Florida) was ice. The T34 in its aircraft application had an integral deicing system however with the turboprops shut off aboard a ship, some sort of external constant deicing method would be needed if the vessel ventured into colder waters.

During winter, the airscrews would presumably project seaspray onto the ship’s deck and superstructure which would then freeze into a cake of solid ice. No solution to this was readily apparent.

The turboprops were very loud; with all four running YAG-37 basically sounded like an airport. Once again, this was not unexpected and not itself a solely limiting factor. The flight deck of a US Navy aircraft carrier during WWII was not exactly quiet however for the future applications envisioned in 1957, the high noise level would be yet another headache.

end of project

The US Navy quickly concluded in 1957 that this was not a feasible system. It was considered so unsuccessful that the research was never classified; the December 1957 issue of All Hands, the US Navy’s magazine, had an article about it listing details such as the turboprop RPMs, horsepower output, etc.

(YAG-37 in Baltimore, MD in 1957. The turboprops are still aboard but the WWII cargo booms have been removed. The striped poles are photography calibration markers.) (Associated Press wirephoto)

YAG-37 still had the buoyancy materials aboard for the cancelled minesweeping trials. The turboprops were removed and the now-powerless YAG-37 was transferred to the Underwater Explosion Research Division of Norfolk Naval Shipyard in Virginia.

YAG-37 was used to measure the effects of aquatic explosions of varying size, distances, and directions from the Liberty Ship hull. By early 1958 YAG-37 was battered and falling apart. The ship’s title transferred back to MARAD which immediately made it available for disposal. The former S.S. John L. Sullivan / YAG-37 was scrapped at Wilmington, NC later in 1958.

a follow-on: MSS-1

(The bizarre MSS-1, a former Liberty Ship, after conversion.)

While the turboprop idea was a flop, some other ideas in YAG-37 still held currency in the US Navy.

During and after WWII the US Navy was interested in an extreme adaptation of the Kreigsmarine’s “sperrbrecher” (“barrage-breaker”) concept. These were 200 merchantmen converted with magnetic, acoustic, and moored sweep gear, which sailed ahead of German surface warships through British minefields in the North and Baltic seas.

(Sperrbrecher 13 had been the freighter S.S. Minerva. This ship survived WWII and continued to clear leftover WWII sea mines until late 1947.) (photo via kbismarck.com website)

Not surprisingly sperrbrechers suffered horrendous losses, both to mines and Allied aircraft.

In 1944 a US Navy project known as XMAP (Experimental Magnetic-Acoustic-Pressure Sweep) was started. It was an unmanned 250′ long, 19′ wide hull weighing 2,880 tons to be towed behind ATFs (WWII oceangoing fleet tugs) to detonate any possible mine of any type. After WWII ended the XMAP project lapsed but was reactivated when the Korean War began in 1950. Beset by colossal cost overruns and missed deadlines, the prototype XMAP-1 was delivered for testing off Florida in 1956. It was a failure and XMAP-1 was scrapped in 1961.

What interested the US Navy by then was the idea of an “unsinkable” minesweeper, a manned ship which would act like a “floating plow”. The difference from the WWII German concept was that sperrbrechers avoided mines if possible; the Americans wanted something that would intentionally encounter them.

The final future objective outlined in 1960 was a new design with a flat, heavily armored lower hull packed with buoyancy and shock-mitigating materials. For proof-of concept work, a WWII Liberty Ship would be used.

The Liberty Ship S.S. Harry L. Glucksman was built in 1944 and chartered by the War Shipping Administration to the Merchants & Miners Transportation Company for the duration of WWII. After the war S.S. Harry L. Glucksman sailed for several owners, the last being the American Coal Shipping Company which returned it to MARAD in 1958 for layup in the James River, VA “ghost fleet”.

On 23 August 1966, title of the ship passed from MARAD to the US Navy. The Liberty Ship was sent to Erie, PA where it was completely gutted, with the whole superstructure, engines, propellers, rudder, cargo booms and just about everything else removed and the interior cargo decks cut open.

Next, the empty hull was towed to the American Shipbuilding Company’s yard at Lorain, OH on Lake Erie. Here a $4.7 million ($40.8 million in 2022 money) contract rebuilt it into an almost unrecognizable configuration. The civilian name was struck and it was known by a brand-new US Navy hull category, MSS-1, with MSS being “special device minesweeper”.

(MSS-1 in April 1969.)

The propulsion was five Murray-Tregurtha Harbormaster outboard engines. Set in sponsons around the ship, each had a commercial Cummins diesel linked to a dynamic power transfer arm, linked to a vertical driveshaft and a horizontal propeller. The driveshaft & propeller could be raised out of the water, and the propeller rotated 360° for steering.

(Three of the five Harbormaster units on MSS-1 when the ship was still in Lake Erie.) (US National Archives photo)

Besides maneuverability, the advantage of this set-up was that there was no propeller shaft seal aft which could fail and flood the ship. The crew was proud of the arrangement and called MSS-1 “the world’s largest outboard boat”.

(photo via navsource website)

A new superstructure was placed forward, containing anything needed to run the ship. The new crew was nine, one officer and eight enlisted sailors. During sweep operations, they all were in a deckhouse high above the superstructure. This deckhouse sat upon four huge piston-type shock absorbers, and was stabilized against directional sway by springloaded tension cables on all four corners. The men sat in cushioned chairs which also had small shock absorbers, and were seat belted in.

Internally, MSS-1 was filled with 144,000 ft³ of buoyancy material from the first deck down to the waterline. Often described as “styrofoam”, it was actually Autofroth I, a trademarked rigid polyurethane developed by the BASF company. This was pressure-pumped or sprayed as a two-part liquid and once hardened, adhered to both the Liberty Ship hull’s steel and itself.

Below the waterline, the compartments were permanently flooded commensurate to sea pressure at the ocean’s surface. It was hoped that this would act as a “membrane”, where a shock wave in the water would impact one side, be attenuated through the steel and ballast water, and then exit the other side. Considering the issues Liberty Ships in merchant service after WWII had with hull cracking, this was optimistic but in any case it was done.

Inside the first deck a gigantic electric induction coil was laid to generate a field detonating magnetic-fuze sea mines. There were various noise generators for use against acoustic-fuzed mines.

There were no weapons aboard, only a basic navigational radar, and basically little else. The amidships area was strengthened to be a helipad. Two kingposts aft serviced towed minesweeping kit.

(The devices under the booms are called a oropesa, and keep a towed underwater object at a set depth and direction away from the host ship.)

MSS-1 was not considered a commissioned warship and was instead a “device” belonging to ComMineLant, the US Navy Atlantic Fleet’s minesweeping command and homeported at Charleston, SC.

During 1967 Congressional hearings for the FY68 naval budget, two additional MSS conversions were requested for operational use in the Vietnam War but funding was not allocated.

From September 1969 to March 1973, MSS-1 conducted tests along the East coast and near the Florida Keys, both alone and in company with traditional minesweepers. In some cases very large explosives were detonated near the ship with the crew aboard.

The US Navy felt the idea held promise but by 1973, cumulative blasts during the four years of tests were starting to wear at the WWII hull. At the same time, American involvement in Vietnam was winding down. MSS-1 was laid up at the Philadelphia, PA mothball yard in September 1973 and scrapped in 1975.

a final postscript

There actually was one situation where the technologies aboard YAG-37 and MSS-1 would have been useful. No WWII ship was used in this instance.

Part of the January 1973 Paris Peace Accords which formally ended American involvement in the Vietnam War mandated that the US Navy clear sea mines it had laid, with a final clause being that an American warship must sail up the Red River into Haiphong to prove that it had been swept.

(USS Washtenaw County (LST-1166) to the left of USS Pitkin County (LST-1082) illustrating the size difference between a Cold War-era and WWII-era tank landing ship.)

(USS Washtenaw County (LST-1166) to the left of USS Pitkin County (LST-1082) illustrating the size difference between a Cold War-era and WWII-era tank landing ship.)

As mentioned above MSS-1 was generally worn out by early 1973 and was only about 10 weeks away from final deactivation; and was hence not considered. Instead a Cold War-era tank landing ship, or LST, was selected. USS Washtenaw County (LST-1166) was already undergoing maintenance at a shipyard in Japan. The US Navy ordered a hurried conversion into a “barrage-breaker” type setup and renumbered it USS Washtenaw County (MSS-2).

(USS Washtenaw County (MSS-2) in North Vietnamese waters during 1973.)

None of the exotic concepts aboard YAG-37 or MSS-1 were included and the changeover from amphibious ship to MSS was fairly minimal. Manned by an all-volunteer skeleton crew, USS Washtenaw County made about a dozen runs in North Vietnamese waters during 1973. No mines were detonated. The ship was decommissioned later in 1973.

Since 1973 there have been no further ships of the MSS type and interest in this concept is defunct.

Reblogged this on Dave Loves History.

LikeLike

The Liberty ship was the backbone of the postwar Greek shipping miracle. I remember reading the special issue on the 100 Liberties of 1947 that started the miracle where it had a list of all Greek owned Liberties showing the last being broken in the early 1980s during that horrible shipping crisis. Of the 722 Liberty ships that were active in 1966, 602 were owned by Greek interests. As far as I know two Liberties have survived to this day, one is in San Francisco and the other is in my hometown, Piraeus and it took a joint Greek and American effort, funded on the Greek side exclusively by shipowners, to bring it there

LikeLiked by 1 person

“Barrage Breaker” is kind of a nautical version of a large roller in front of a tank to detonate land mines. It has enough mass to absorb the explosions and keep rolling. Way more complicated at sea!

LikeLiked by 1 person

While I was reading it says that work began on the S.S. John L. Sullivan on May 2,1943 and finished on June 7,1953.This must be a typo.

LikeLike

lol yes it was

LikeLike

I’m 275 pages into writing a military history of Afghanistan. I read your “WWII gear in Afghan use: Part III – tanks and artillery”. It is a fine article. I have some specific questions. Would you consider answering them? I will cite you in the book.

LikeLike

I can try but I wrote that years and years ago, I dont have much of the source material anymore.

LikeLike

[…] More here – https://wwiiafterwwii.wordpress.com/2022/02/20/turboprop-powered-liberty-ship/ […]

LikeLike